Testing Services

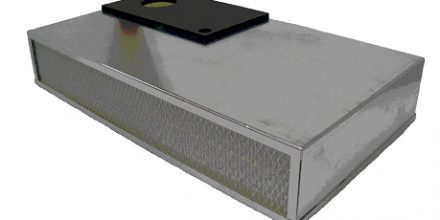

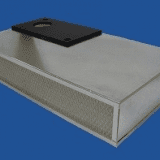

In October 2017 – APC expanded its critical air filter testing capabilities with two new test chambers designed and built to accommodate maximum filter sizes of 72” x 24” x 12” and 48” x 48” x 12”. These new filter test chambers are designed and engineered by APC Filtration and capable of performing filter leak testing and fractional efficiency filter testing to American (IEST), European (EN) and pending ISO filter test standards for HEPA and ULPA filters. ISO 29463-1:2017 test standards are in the final review stages before global filter industry implementation.

Air Filter Design, Engineering & Testing

APC’s engineering group provides 3D filter modeling capabilities that allow us to quickly design, model and test air filter concepts for fit, function, performance and longevity across a wide range of appliance and equipment applications. We specialize in custom filter configurations that meet unique OEM specifications across the pharmaceutical, military, and industrial sectors. Our engineering group collaborates closely with your team throughout the design process to develop an initial concept and move through validation testing.

Throughout this process, we have created an efficient RFQ program to meet your cost and timeline requirements during testing. This allows us to deliver innovative filtration solutions that exceed your performance expectations, while also maintaining cost-effectiveness and extending the lifespan of all our products.

Every new custom design our team creates with your application needs in mind undergoes rigorous testing protocols to ensure reliability and compliance with industry standards before production.

APC’s New ISO 6 Clean Room Increases Filter Testing Capabilities

Increased demand for tighter ISO controls in high purity and critical air filter production also requires filter testing labs to be climate controlled to ensure temperature and humidity remain consistent during filter testing operations. Critical air filters, including HEPA and ULPA filters are susceptible to failure if environmental conditions during filter media storage, pleating, assembly and testing operations are not consistent.

Maintaining consistent environmental parameters in our new clean room allows us to better test filter capabilities while eliminating any additional variables in the process. Tracking contaminant levels in real time, our clean room capabilities help keep our products providing the best filtration performance and lifespan on the market. This new process of quality control ensures your laboratory, medical facility, or pharmaceutical research facility can proceed with the peace of mind of contaminant-free air.

Not only does this allow us to ensure product quality and stand behind every product we produce, but we prove our value as your reliable partner in air quality and filtration for the long-term. We are committed to quality assurance and maintaining compliance with regulatory standards for a wide range of industries, helping you stay on top of changing procedures and cleanliness standards.

Air Filter Testing Laboratories

In addition to our standard testing capabilities listed below, APC is the only air filter manufacturer within our industry capable of providing appliance and/or equipment integrity testing to identify problems areas.

This specialized method of testing was developed through decades of industry experience, allowing us to detect even microscopic leaks in performance, and deficiencies that could compromise the system’s effectiveness over time.

Regulatory compliance and safety are our top priorities.

Feedback is provided to ensure your assembly operations are air-tight and leak-proof. APC provides air filter testing to ASTM, ASHRAE, BS EN1822 and IEST CC-007.1 (HEPA & ULPA) ISO and SAE standards. In addition, we work with laboratories and Universities in the USA and Canada for third-party testing as required.

- Appliance/Equipment HEPA Filter Integrity Testing

- Fractional Efficiency Testing (7 channel – 0.3 to 10µm)

- Dust Load Testing (up to 6000 g)

- LumiScan Leak Detection Testing

Check our Summary of Testing Services

For additional details on filter ratings and testing standards, please see below or contact us directly to determine what APC Filtration can provide for you. We understand that your industry depends on proper testing and quality-controlled filtration solutions. From disaster recovery to infection control and biological safety applications, APC Filtration’s comprehensive testing ensures your filters will perform in the field, protecting both your equipment and end-users even in the most demanding situations.

Custom Filter Design

From concept through production, we’ve got what you’re looking for. Our collaborative design process begins with understanding your unique challenges and performance requirements, and designing the right filtration for your needs. Utilizing advanced 3D modeling and CFD analysis, we created solutions that integrate directly with your equipment, all while meeting operational demands and regulatory standards – even in the most challenging environments.

Get in touch with our team today to start a conversation. Let us build something that lasts.

Diverse Range of Industries

Serving a diverse range of sectors where air quality is a critical aspect of the work and final product, APC Filtration is dedicated to providing reliable custom solutions for your business. Each of our air filter testing chambers allows you to perform air quality testing in laboratory settings while adhering to strict industry-specific regulations.

In cabin air filtration, we ensure the operators of heavy machinery, protective equipment, and specialized vehicles all breathe clean air, even in the most challenging conditions. Medical and pharmaceutical applications benefit from specialized HEPA and ULPA filtration solutions that maintain strict levels of cleanliness without as minimal maintenance.