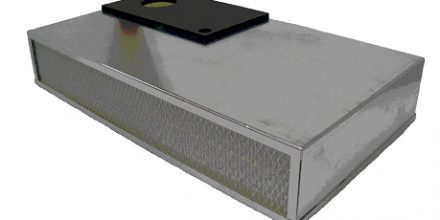

Two-Stage Filter & Frame for Biological Safety Cabinet

Industry: Biological Safety Cabinets for Europe

Application: Design a two stage redundant HEPA Filter to meet EN1822 Standard H14 (99.995% @0.3 µm)

APC Filtration Inc. was contacted by a biological safety cabinet manufacturer who required design of a two-stage HEPA filter. The second stage HEPA filter would serve as a safety measure should the first stage HEPA fail. A 1″ w.g. pressure drop is achievable in a single stage filter, but presents a challenge for a two stage design to meet EN1822 H14 filter efficiency and testing requirement. Other needs included metal-free, non-toxic raw materials to eliminate hazardous gases during disposal by incineration. Packaging design had to insure filters would not be damaged in shipping.

OUR CUSTOM FILTER DESIGN INCORPORATED THE FOLLOWING IMPROVEMENTS:

- Filter Frame: We enlisted the services of a wood specialist, who helped determine raw material selection, sealed seam construction and frame assembly to create a leak-free high density wood frame.

- Non-Toxic Materials: We eliminated all toxic materials previously in use.

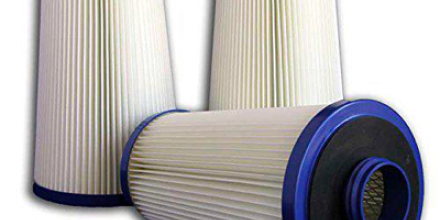

- Reduced Pressure Drop: APC tested several combinations of secondary and primary filter medias, varying the filter area of each to meet H14 efficiency. We then tested airflow dynamics between the secondary and primary filters to determine the optimal spacing and pleat direction between each pleat pack, until successfully achieving a 1″w.g. pressure drop.

- Custom Designed Packaging: Was created to eliminate shipping damage.

Two years after providing a solution for this client’s filtration dilemma, today APC supplies 100% of all their critical air filter requirements.

To learn more about this biological safety cabinet filter project, our HEPA filters, or about our other products and services, please.