APC Filtration: Top Choice for Activated Carbon Filter Manufacturers

APC Filtration Inc. is an ISO 9001:2015 certified manufacturer providing over 40 years experience in critical air filter design, engineering, manufacturing, filter testing and appliance/equipment integrity testing for global OEM’s of industrial, commercial and household equipment.

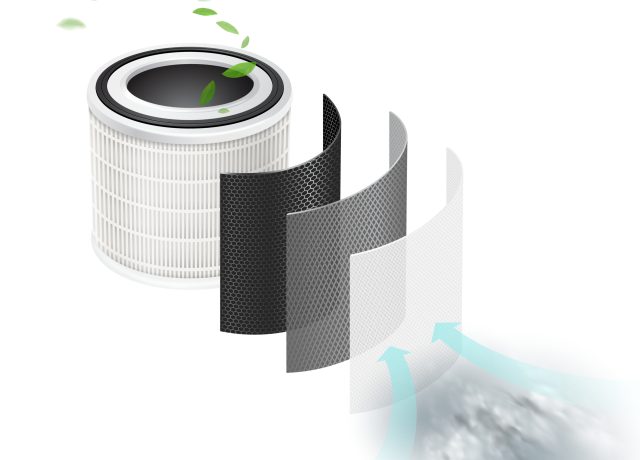

Custom Carbon Filtration Systems

An activated carbon filter, manufactured from raw materials that include coconut shell, wood, and coal, remove volatile organic compounds (VOCs), odors, and other gaseous pollutants from the air.

Selecting the right filtration for your application measurably improves performance, decreases the frequency of carbon exchanges, and helps lower your operating costs.

What is activated carbon?

Carbon filters are most commonly used to remove gases, designed to filter gases through a bed of activated carbon (also called activated charcoal) to combat volatile organic compounds (VOCs). They remove odors from the air, such as the smell of tobacco smoke. They do not remove fine dust particulates like mold, dust, or pollen from the air.

How do activated carbon filters trap gaseous pollutants?

Activated carbon filters remove pollutants from the air with a process known as adsorption, which is different from absorption. Ad-sorption, allows VOCs to stick to the carbon, whereas ab-sorption allows pollutants to be absorbed inside the structure itself, like a sponge.

The process of adsorption allows carbon filters to remove organic VOCs from the air. As VOCs fill up the adsorption sites of the activated carbon, the carbon bed becomes saturated and the product needs to be changed. In fact, chemicals with a greater affinity for an adsorption site can displace those with lesser affinity, and the affinity of a given chemical for the sorbent is highly dependent on ambient conditions such as temperature and relative humidity. As environmental conditions change, different chemicals may be released. When a carbon air filter is saturated with water or chemicals, it will give off a strange odor. This is a strong indicator it’s time to change your carbon filter, especially if it is a HEPA filter.

Gas purification

Impregnated activated carbon is used to treat flue gases in coal-fired generation plants and other air pollution control applications. Carbon can be specifically impregnated for removal of acid gases, ammonia and amines, aldehydes, radio-active iodine, mercury and inorganic gases such as arsine and phosphine. Carbon impregnated with metal-oxide targets inorganic gases including HCN, H2S, phosphine and arsine.

Carbon Filter Types

APC provides custom designed carbon filters for each OEM’s specific requirement, equipment or device.

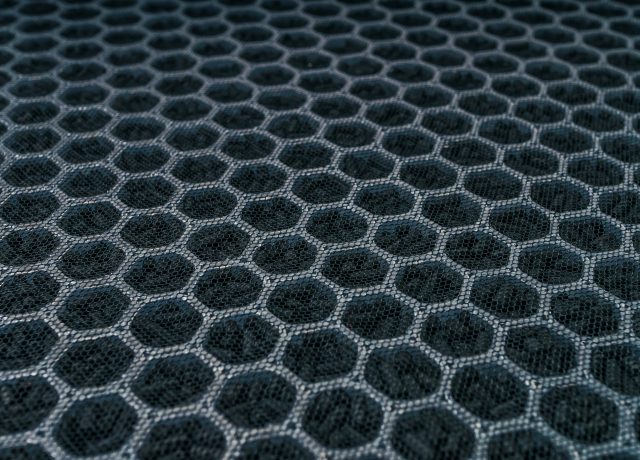

- Panel Filters with honeycomb encased granular activated carbon (GAC)

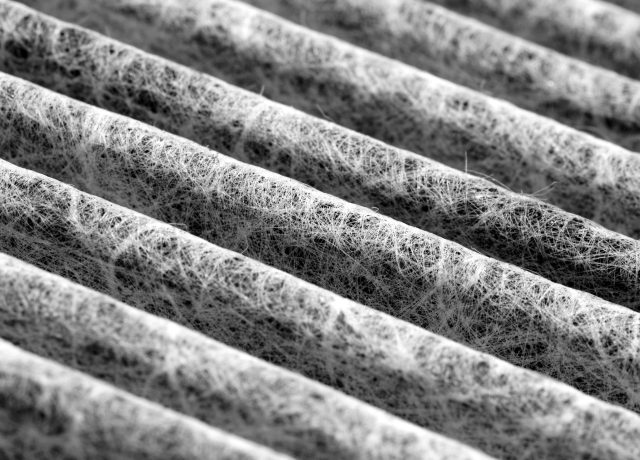

- Panel and Radial Filters with pleated carbon media