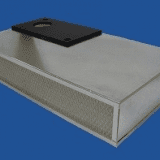

Private Label Air Filters - Custom OEM Air Filter Design

APC Filtration Inc. is an ISO 9001:2015 certified manufacturer providing over over 40 years of experience in critical design, engineering, and air filter testing for global OEMs of industrial, commercial, and household equipment. We specialize in custom OEM filters designed and engineered to provide superior fit, function and performance with the longest filter life possible.

APC Filtration Inc., is a specialty custom manufacturer, flexible and capable of providing quick turnaround on product design, prototyping, testing and production. Our annual production capacity depends on the size and complexity of the air filter. We can supply up to 1,000,000 small filters annually per year or fewer than 100,000 filters for our largest size. Our filters are designed to prevent oil and other chemicals from degrading the filter’s housing, leading to lasting durability and premium lifecycle benefits.

Custom air filter specifically designed and engineered to: – provide superior performance, – proper function, fit, and seal – the longest filter life possible.

We are your filter manufacturer, providing unique, proprietary, and/or patented air filter designs for our clients, along with rapid prototype modeling and filter testing to meet North American and European standards. Trust APC for all your custom air filter needs.

ISO 9001:2015 Certified Manufacturer for Filters

Air filter leak testing, fractional efficiency testing, air filter certification, appliance/equipment integrity testing, dust load testing, and custom filter design including private label product manufacturing and contracting for air filters are just a few benefits we provide.

APC qualifies each custom design through in-house air performance laboratory testing to meet the following test standards for customers:

- North America – ASTM, ASHRAE and IEST standards

- Europe & Asia – BS EN1822-05:2009 standards.

Filtration Expertise

APC logistics provide just-in-time, consolidated shipping, global freight management, global warehousing and Kanban services for all your filter requirements between our warehouse locations in the USA., Canada and China.

For additional details and to learn more about our custom air filter manufacturing capabilities please see below, view our HEPA filter and ULPA filter projects, or contact us directly to determine what APC Filtration can provide you.