Aseptic Filtration Equipment – Custom HEPA Filter Design

Industry: Food & Pharmaceutical Equipment

Application: Aseptic Processing

Aseptic processing is the process by which a sterile (aseptic) product (typically food or pharmaceutical) is packaged in a sterile container in a way that maintains sterility.

Sterility is achieved with a flash-heating process (temperature between 195 and 295 °F (91 to 146 °C) which retains more nutrients and uses less energy than conventional sterilization techniques. Pharmaceutical Sterile processing includes use of clean rooms, bacteria retaining filters, dry or steam heat. Aseptic food preservation methods allow processed food to keep for long periods of time without preservatives, as long as they are not opened.

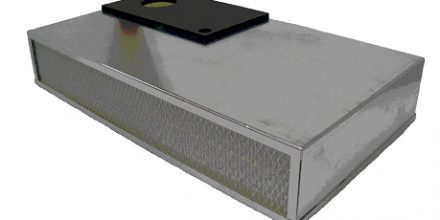

APC was contacted by the equipment manufacturer to design a custom made HEPA filter for their equipment. The filter body and installation assembly was designed entirely out of 316, #4 brushed stainless steel to withstand the disinfectant cycles that use vaporized hydrogen peroxide.

Custom designed packaging was designed to prevent filter damage and insure filter integrity when our client required drop shipping replacement filters to their global equipment clients.

To learn more about this or our other biological safety cabinet filter projects, or about our other products and services, please contact APC Filtration, Inc.

What is This Type of Technology?

Aseptic filtration is a type of filtration technology that ensures absolute sterility in pharmaceutical products and food processing environments. This specialized type of filtration process removes microorganisms, particulates, and contaminates from air and liquids without introducing any new contaminants through open air exposure.

At APC Filtration, we design custom HEPA and ULPA filters that achieve sterility ratings up to 99.9995% at 0.12 microns – ensuring your compliance with ISO standards and regulatory requirements across industries.

Our systems integrate seamlessly into clean rooms, biological safety cabinets, and processing equipment to maintain the sterility of controlled environments. With over 40 years of engineering expertise to back our custom filtration designs, we create solutions that withstand rigorous sterilization protocols, including vaporized hydrogen peroxide cycles, all without compromising the integrity of your filtration performance.

How This Sterile Filtration Process Outperforms

APC Filtration’s aseptic technology delivers superior performance compared to conventional filtration methods through innovative design and over 40 years of research and precision engineering. Our custom HEPA and ULPA filters provide exceptional resistance to durability loss due to disinfectants or sterilization agents. Without particle shedding or degradation, this kind of durability translates to lower lifecycle costs for the filtration system and less frequent replacement.

Not only does this lower the cost of this fill technology over time, but it reduces downtime and contamination risk during changeouts. These filters last through multiple cleaning cycles, providing the durability you’ve come to expect from the rest of our product line.

Aseptic Filter Formats: Selection Guide

Choosing the right aseptic filter depends on your particular application, as well as the equipment you are using the filters in. At APC Filtration, we offer a range of configurations to meet a diverse range of manufacturer needs.

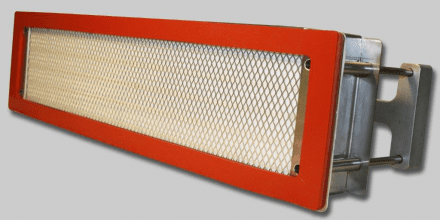

Panel Filters – ideal for single laminar airflow applications and equipment that has space constraints.

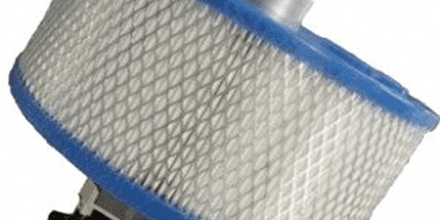

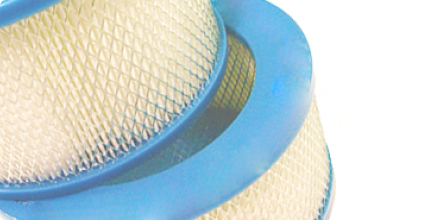

Cylindrical Filters – ideal for in-line processing and circular sterilizing filtration capabilities for flow rates from 1 to 5000 SCFM.

Mini-Pleat Filters – Ideal for an extended dust-holding capacity and minimal pressure drop.

Each of our formats can be customized with specialized media, gasket materials that are compatible with a range of disinfection protocols, and different mounting solutions designed for your specific equipment needs. Our engineering team works directly with your design staff to recommend the most effective and efficient format based on your processing requirements and performance standards, and we’re happy to build a custom solution for your needs. Get in touch with our team today to learn more about our aseptic formats and which one is right for your needs.

Your Choice for Specialized Filters for Sterile Product Operations

At APC Filtration, we’ve established ourselves as the trusted partner for manufacturers like you that require specialized sterile filtration. Our comprehensive approach to customized filter solutions is top of the line, making us a top choice for including analyzing your sterility requirements, process conditions, and equipment constraints before creating a system that integrates seamlessly with your equipment.

We specialize in creating solutions for every type of application, regardless of how challenging the engineering is; including extreme temperature environments, frequent chemical exposure, and applications that require performance documentation.

Partner with APC Filtration for solutions engineered to enhance the performance of your aseptic processing equipment.